How to use and validate iHP® Cycles

Ionized Hydrogen Peroxide (iHP®) iHP® is hydrogen peroxide, which is split into reactive oxygen species (ROS) by Binary Ionization Technology (BIT), increasing its efficacy and effectiveness as a disinfectant. iHP® is also classified as a sterilant, meaning that it can achieve sterilization of a surface, material, or room. As a sterilant, it can eradicate all […]

Choosing the Right Decontamination Method for Your Facility

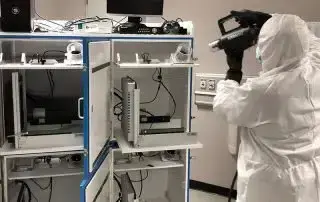

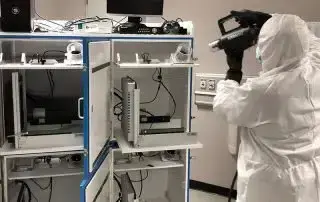

Cleanroom decontamination isn’t one method fits all. The right approach depends on several variables: the type of facility, the classification level, the product being manufactured, the type of contamination, and the materials and equipment within the environment. Choosing the wrong method can lead to incomplete sterilization, damage to sensitive systems, or unnecessary downtime. At Vibraclean, […]

Environmental Monitoring for Cleanrooms: Strategies for Effective Control

Cleanrooms are critical environments for many industries, including pharmaceuticals, biotech, and electronics manufacturing. These environments require stringent control of particulate and microbial contamination to ensure product quality, safety, and efficacy. One essential aspect of maintaining these cleanroom environments is environmental monitoring. Environmental monitoring involves regularly testing and evaluating various environmental factors, including air and surface […]

Why Contamination Control is Important

Contamination control is a critical aspect of cleanroom operations in GMP facilities. A cleanroom environment must be maintained at a level that is free of contaminants, which could compromise the integrity of the products being manufactured. Best practices for contamination control in cleanrooms and GMP facilities include: 1. Proper Gowning and Decontamination Techniques: Gowning and […]

Key Principles of Contamination Control

Contamination control is a critical aspect of cleanroom operations in the pharmaceutical, biotechnology, and medical device industries. Cleanrooms and GMP facilities are designed to control and minimize the introduction, generation, and spread of contaminants that can compromise the integrity of the manufacturing processes and products. Contaminants in a cleanroom can come from various sources, including […]