Cleanroom decontamination isn’t one method fits all. The right approach depends on several variables: the type of facility, the classification level, the product being manufactured, the type of contamination, and the materials and equipment within the environment. Choosing the wrong method can lead to incomplete sterilization, damage to sensitive systems, or unnecessary downtime.

At Vibraclean, selecting a decontamination method begins with a thorough assessment. We evaluate the cleanroom’s layout, surfaces, airflow design, risk level, and operational needs before recommending a solution. Our goal is to match the method to the facility—not the other way around.

Some cleanrooms require deep, sporicidal decontamination, while others benefit from routine, lower-intensity cleaning to maintain baseline cleanliness. Here are a few of the primary decontamination methods we consider and how we determine what’s best for each client:

Manual Disinfection

Manual cleaning is the foundation of contamination control. This involves trained technicians applying disinfectants using wipes, mops, and sprays. Manual disinfection is ideal for daily or weekly cleaning schedules, especially in lower-risk areas or as part of routine maintenance. However, it requires consistency, proper technique, and validated contact times to be effective.

We recommend manual methods for:

- Routine cleaning in ISO Class 7–8 environments

- Facilities with sensitive equipment that cannot be exposed to vapor or fog

- Areas where localized contamination is present

Fogging (Aerosolized Disinfectants)

Fogging uses aerosolized chemical disinfectants to create a fine mist that covers all surfaces, including hard-to-reach areas. It’s an efficient way to reduce microbial load in larger spaces or high-touch zones. The key to fogging is selecting a disinfectant that’s compatible with the cleanroom’s materials and validated for efficacy.

We recommend fogging for:

- Facilities with large surface areas to disinfect

- Cleanrooms transitioning between product batches

- Supplementing manual cleaning for broader coverage

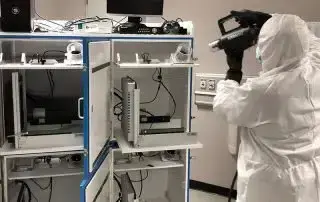

Ionized Hydrogen Peroxide (iHP)

iHP is one of the most advanced decontamination methods available. It disperses ionized hydrogen peroxide vapor throughout the environment, offering complete, residue-free sterilization. iHP is especially effective at eliminating a wide range of pathogens without damaging equipment or leaving behind corrosive byproducts.

We recommend iHP for:

- Sterile pharmaceutical production areas (ISO Class 5–6)

- Deep cleaning after shutdowns or contamination events

- Facilities with complex equipment that require non-contact sterilization

Factors That Influence Method Selection

Several factors influence which method is best:

- Cleanroom classification: Higher classifications require more thorough, validated methods.

- Type of contamination: Bacterial, fungal, or particulate threats may require different approaches.

- Equipment sensitivity: Some sterilants may damage electronics, filters, or finishes.

- Regulatory requirements: Specific methods may be required or recommended by internal SOPs or external guidelines.

- Downtime availability: Some methods require more drying, aeration, or validation time than others.

Vibraclean takes all of these into account to create a customized plan that prioritizes safety, effectiveness, and operational continuity. Our technicians are trained in a range of decontamination techniques and disinfectant chemistries to ensure that each job is matched with the best available tools.

No matter which method is selected, documentation and validation remain core to our service. We provide detailed records of products used, contact times, procedures followed, and environmental results—ensuring compliance and peace of mind.

Cleanroom environments are not all the same. The decontamination process shouldn’t be either. Vibraclean helps pharmaceutical and biotech facilities make informed choices about how to maintain sterility, one method at a time. Contact us for more information.