Ionized Hydrogen Peroxide (iHP®)

iHP® is hydrogen peroxide, which is split into reactive oxygen species (ROS) by Binary Ionization Technology (BIT), increasing its efficacy and effectiveness as a disinfectant. iHP® is also classified as a sterilant, meaning that it can achieve sterilization of a surface, material, or room. As a sterilant, it can eradicate all types of microorganisms as defined by the hierarchy of disinfection.

iHP® is advantageous in part due to its ease of use and favorable safety profile. iHP® degrades into nontoxic by-products by recombining into water and oxygen molecules, which can be easily and safely exhausted back into the environment. No special filters or scrubbers are needed, unlike other gaseous disinfectants that are in use. Additionally, iHP® has excellent material compatibility, meaning it is gentle on equipment and construction materials while still effectively reducing bioburden.

Using iHP®

iHP® is generated by a specialized generator that emits a stream of specially formulated hydrogen peroxide via a high-voltage plasma arc. This action splits the H2O2 molecule into ROS, such as hydroxyl radicals. Coupled with the small particle sizes that are generated, plus the high velocity that is achieved, iHP® can penetrate the smallest openings within the space. As an oxidizing agent, iHP® eradicates microorganisms by lysing them.

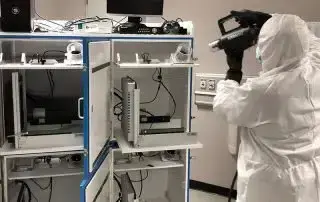

iHP® generators can be portable or integratable, and the application of iHP® can be in the form of whole space fogging or direct surface spraying. For whole-room fogging, applicator heads are set up on tripods and arranged in a formation that allows the iHP® to move around the room. With direct surface spraying, the applicator heads are switched to handheld mode, and surfaces within a room or on materials are directly sprayed with iHP®.

iHP® Biodecontamination Cycle Development and Validation

Developing and validating your iHP® biodecontamination (biodecon) cycle is an important part of using iHP® in your cleanroom or facility. When developing your biodecon cycle, you must consider your room size and layout, as well as the level of disinfection you want to achieve. A biodecon cycle has three phases: the Injection phase, the Dwell phase, and the Aeration phase. Depending on your room size, equipment layout, and air changes per hour, these three times can vary from room to room and facility to facility:

Injection phase: During the Injection phase, iHP® is injected into the space. Adequate time is required for the whole calculated dose to be injected into the room.

Dwell phase: During the Dwell phase, the iHP® circulates and eradicates any microorganisms it encounters. Enough time must be allowed for the iHP® to circulate and work effectively.

Aeration phase: During the Aeration phase, the iHP® is diluted with circulating air and is removed from the room. In parallel, the ROS recombine to create water and oxygen. During this phase, the H2O2 ppm must drop below 1ppm to be deemed safe for entry again.

When developing these phases, there are tools you can use to help.

- H2O2 monitor: This device monitors your H2O2 levels and indicates when the desired H2O2 dose is reached and how long it is sustained for. In addition, a H2O2 monitor is used to determine how long the aeration phase should be set for.

- Chemical indicators (CIs): CIs are placed around the space being deconned and indicate, via color change, whether H2O2 is reaching that location. The greater the color change, the more H2O2 it is being exposed to. Once you have developed your cycle, then it is time to validate it. Validation of an iHP® cycle requires some specialized equipment and resources, but execution is straightforward. Biological indicators (BIs) are the key component when validating your iHP® cycle. Similar to how CIs are used in the development stage, BIs are used in the validation stage by being placed around the room in areas identified during development. BIs harbor highly resistant bacteria that are only inactivated when exposed to the required dose of iHP®.

After completing your validation cycle(s), the exposed BIs are collected, placed in growth media, and incubated at 60°C for 7 days. If no growth is observed after 7 days, then the biodecontamination cycle was successful and is now validated and ready for use. Contact us for more information.