Home

Industries

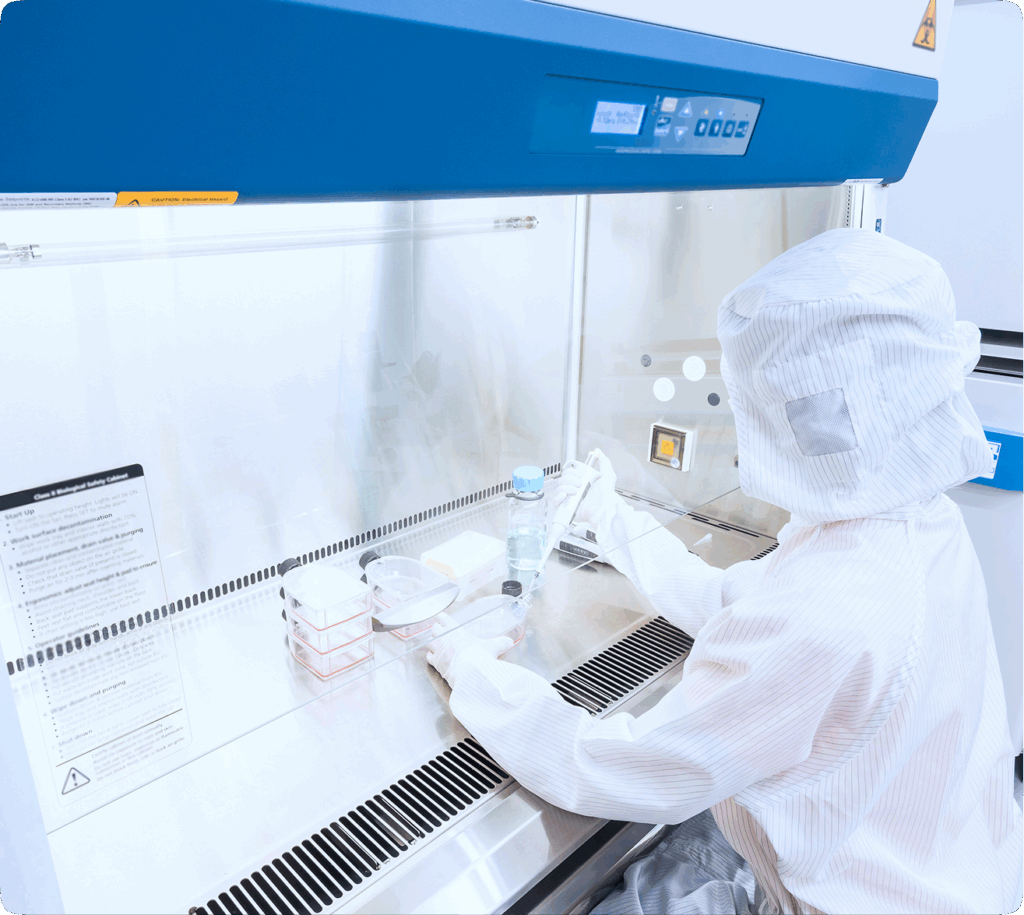

Labs and Research Facilities Cleanroom Cleaning

We free researchers to focus on science while keeping rooms inspection-ready.

In labs and research facilities, timelines are tight, projects shift quickly, and experiments cannot wait. Researchers need to move seamlessly from one project to the next without worrying about residues, scheduling conflicts, or documentation gaps. When cleaning disrupts experiments or documentation fails to keep pace with scale-up, both scientific progress and compliance readiness are put at risk.

Our programs are designed to stabilize shared environments, protect sensitive materials, and ensure documentation aligns with your procedures as projects progress toward manufacturing.

With Vibraclean, your teams stay focused on discovery while we keep every space inspection-ready.

The Problems We Solve

Leftover residues, tool carryover, and unclear wipe sequences in hoods and enclosures compromise repeatability.

We prevent these risks with room- and equipment-specific instructions, segregated tool sets, and defined wipe sequences for fume hoods, biological safety cabinets, and glove boxes.

As projects move closer to manufacturing, ad hoc records and missing links to procedures often become roadblocks.

Our solution provides room-level logs that mirror your procedures, training records for assigned technicians, and summaries that support smooth technology transfer.

When crews arrive at the wrong time or miss windows between runs, research progress is delayed.

We build shift- and experiment-aware schedules, stage kits in advance, and verify completion in the room before release so science stays on track.

Improper cleaning agents can leave films on optics, etch view panels, or damage seals.

We avoid this by using surface-compatible chemistries, defined rotation plans, and residue removal steps designed specifically for sensitive materials.

Where We Support

Active Pharmaceutical Ingredient Synthesis and Bioconjugation

Solvent residues, cross-project carryover, and tight windows between runs are constant challenges.

We deploy solvent-aware wipe sequences, tool segregation, and schedules that protect run readiness without disrupting research.

Small Molecule Manufacturing and Development Labs

Shared rooms with multiple projects often create line clearance confusion and documentation gaps.

Our programs include clear changeover checklists, straightforward room instructions, and logs that link directly to your standard operating procedures.

What’s In It for You

Schedules that serve science.

Shift- and experiment-aware plans hit windows between runs without bumping experiments.

Clean changeovers between projects.

Room- and equipment-specific instructions, tool segregation, and line clearance routines ensure every project starts clean.

Documentation that grows with you.

Logs and training records support technology transfer and ease the path toward manufacturing.

Protection for sensitive materials and equipment.

Surface-compatible chemistries and residue control keep optics, seals, and finishes intact.

Steady routines without draining researchers.

Trained crews and in-room verification keep standards high while freeing scientists to focus on their work.

Audit-Ready Documentation

Room-level logs with who, what, when, and result

Technician training records

Procedure crosswalks

Deviation notes with corrective and preventive

action handoff

Inspection readiness checklist tied to

your environmental monitoring approach

Proof In Practice

Tailored Solutions

Custom cleaning and disinfection programs designed for your facility’s unique compliance needs.

25+ Years Expertise

Decades of proven experience delivering critical disinfection across regulated industries.

10+ Years Research

Extensive particle and bio-burden control expertise across multiple industries.