Home

Industries

Radiopharmaceuticals Cleanroom Cleaning

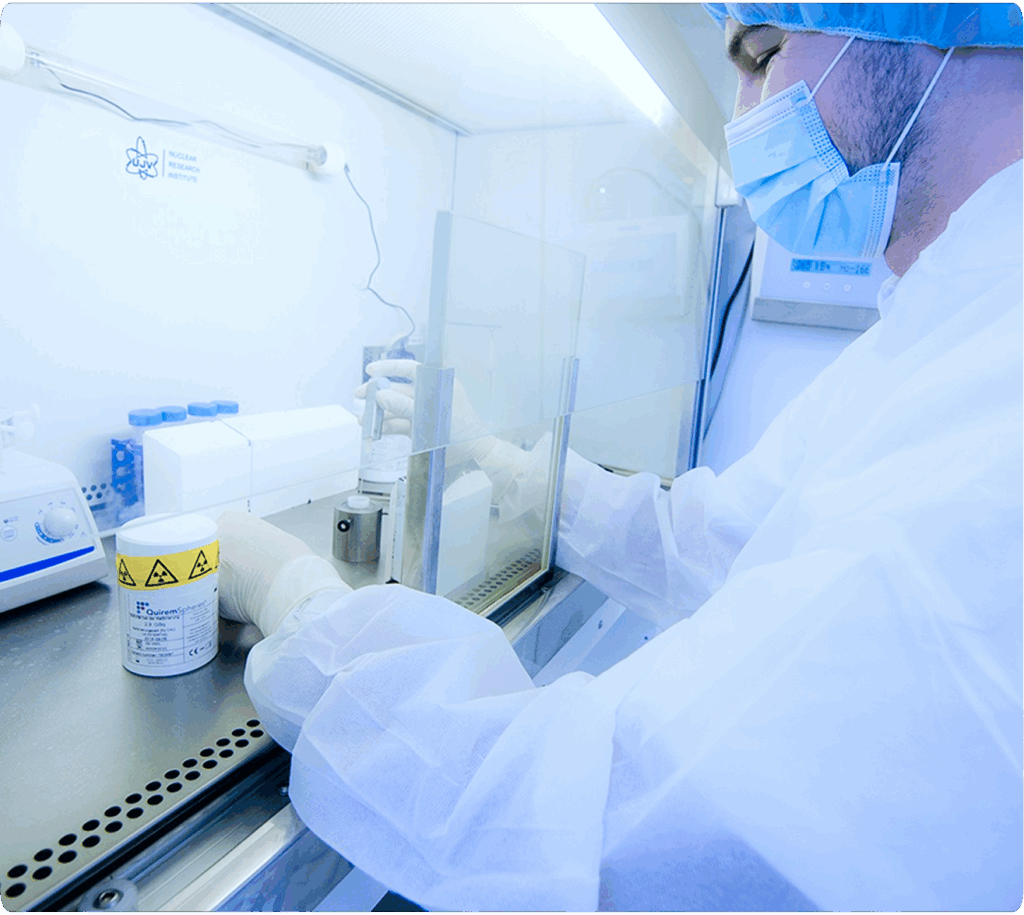

In radiopharmaceutical production, every hour matters. Morning release deadlines leave no margin for error, yet sterility and safety standards cannot be compromised. Hot cells and isolators must be cleaned precisely, surfaces must remain clear, and records must satisfy both quality assurance and radiation safety teams. A single missed step can delay doses, put patients at risk, and invite inspection findings.

Our programs are designed to keep release schedules predictable while protecting critical equipment and documentation integrity. With Vibraclean, radiopharmaceutical suites stay ready for inspection and production so your team can focus on delivering life-saving doses on time.

The Problems We Solve

- What it looks like

Morning release deadlines, last minute holds, and missed patient doses.

We keep suites ready with time-boxed routines, pre-staged kits, and in-room verification before production begins.

- How we prevent itTime boxed routines, pre staged kits, and in room verification so the suite is ready when production begins.

- What it looks like

Clouded view panels, sticky residues, and worn seals are common outcomes of poor routines.

- How we prevent itOur approach uses compatible chemistries, defined contact times, residue removal steps, and clear sequences for both inside and outside surfaces.

- What it looks like

Incomplete logs and mismatched steps can fail to satisfy reviewers.

- How we prevent itWe provide room-level logs with who, what, when, and result, technician training records, and crosswalks that map directly to your procedures.

- What it looks like

Unclear actions or undefined clearance criteria create risk during spill response.

- How we prevent itWe follow targeted decontamination protocols with measured contact times and sign-off procedures aligned with both environmental monitoring and radiation safety requirements.

Where We Support

Speed to release, compatibility with isolators and hot cells,

and strict sterility expectations make this environment

uniquely demanding.

We apply time-aware routines, isolator-specific

sequences, compatible chemistries, and documentation tailored for rapid review by quality assurance and

radiation safety teams.

What’s In It for You

Suites are ready for on-time morning releases with time-boxed routines, pre-staged kits, and in-room verification that support early dose schedules.

Clarity is preserved in isolators and hot cells through inside and outside sequences, measured contact times, and residue removal steps that protect view panels and seals.

Records satisfy both quality and radiation safety teams with shift release checks, room logs, training records, and concise summaries reviewers can approve quickly.

Spills and maintenance delays are contained with measured, documented decontamination that returns suites to service on a defined timeline.

Critical equipment stays protected thanks to chemistries validated for the specific materials in use, eliminating guesswork.

Audit-Ready Documentation

Room and shift release logs

Technician training records

Procedure crosswalks

Deviation notes with corrective and preventive action handoff

Inspection readiness checklist tied to environmental monitoring and radiation safety requirements

Proof In Practice

Tailored Solutions

Custom cleaning and disinfection programs designed for your facility’s unique compliance needs.

25+ Years Expertise

Decades of proven experience delivering critical disinfection across regulated industries.

10+ Years Research

Extensive particle and bio-burden control expertise across multiple industries.